PCA Articles

Debunking The Myths on Professional Painter’s Tape

While painting straight lines on a wall might not sound like a complex job for most professional contractors, think about how the job would look like with an inadequate tape?

As a demanding professional painter, you have probably tested a wide array of brands and tapes on the market and we ought to debunk the most common myths to help you find the best match out there.

Delve with us into some interesting facts and make an informed decision for your business.

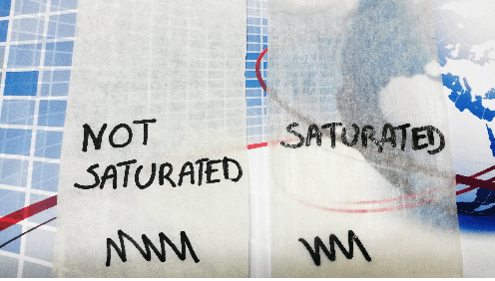

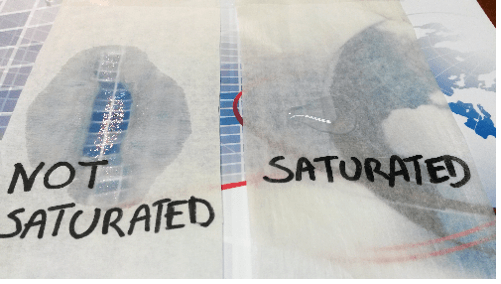

Transparency vs. Permeability

In the market, we often hear “Your tape will not prevent bleed, I can see through it“. We agree to disagree! Transparency and permeability are two different physical features. Simple analogy: you can see through a bottle but water can’t flow out!

When the saturation process is well done, it improves the transparency of the raw paper. Saturation transforms normal paper into a material able to block bleed. A droplet is immediately absorbed by the raw paper while the drop remains in place and doesn’t bleed on a well-saturated paper.

Seeing through is the evidence of an effective manufacturing process and we will continue to advocate for a quality saturation process.

-> Vibac Expert TIP: a non-transparent roll should give you a solid cue that the saturation process or the paper quality is not up to your standard as a painting contractor.

When thinner is better

It is widely assumed that thicker masking tapes are the best, and our answer is a clear simple NO. Paper thickness does not prevent bleed, paper saturation process does!

This could be true for certain kinds of tapes, but does not apply to masking or professional painter’s tapes. As a matter of fact, thinner tapers:

- Are more conformable to uneven surfaces

- provide sharper paint lines

- offer an overall better quality paint job

You are probably wondering the science behind it and we ask our experts to give a simple equation to all tape nerds out there:

Proprietary adhesive formulation

+ the best natural rubber adhesive and cross linked resins

+ a perfect coating process

= using only what is strictly necessary without the need to add more materials to compensate inconsistency or poor performances.

The right balance of Stickiness: adhesive matters!

It is common to hear that painter’s tapes must have very high adhesion levels, which is another myth we would like to debunk. The tape’s adhesion level should correlate to the type of surface you’re planning to mask.

A tape that is too sticky will remain in place really well, but the removal process will cause problems. High adhesion, if not balanced by great tensile strength, often results in tape tearing when removed, and will cause damage to the surface.

A tape that is not sticky enough will most probably force paint contractors to double back to make sure they are in the correct spot, without ensuring that the tape will stick to the surfaces. What’s the point?

At Vibac, we designed our adhesion levels to assure the proper holding power on any surface while removing without residue, even after been on place for a longer time or in challenging situation (e.g. UV exposure). Our wide range of tapes will provide solutions whether you paint a delicate surface (washi) or rough surfaces.

You want to ensure you have the best tape out there that will offer the satisfying crisp lines for your most demanding painting projects? Get your job done right with Vibac. You won’t have to scrape away adhesive from low-quality tapes anymore, because we promise quality and high performance to each and every paint contractors.

Vibac is one of the World’s leading masking tape manufacturers and partners for the automotive refinish, Painting and Hardware, Marine and Construction markets.

For more than 40 years, we have surpassed the industry’s standards and have been recognized for our complete range of premium + high performance masking tapes for professional painting contractors.

Having a fully integrated manufacturing process & total ownership of the products, we offer:

- Paper production (in our own paper mill)

- In-house paper full saturation process

- In-house Coating formulation and process

- Proprietary release formulation (including a full waterproof release)

- In house Converting processes

Vibac has the ability to serve you at different quantity levels (boxes, pallets, containers) and is one of the main private label suppliers on the market.

About The Author

Dick Driggers is the National Sales Manager / Paint & Hardware at Vibac Group, where he has been a part of the masking tape development division for nearly two years.Dick began his career in sales in 1974, after attending Wofford College on an academic and athletic scholarship. He worked for a manufacturer’s agency out of Florida for three years before launching his own firm, The Driggers Agency, representing some of the top manufacturers in the paint industry. Vibac Group, one of his better clients, was interested in hiring him as their sales manager for the United States and Canada.

His primary responsibility at the company is to expand the brand in the painting, hardware, and construction industries.